SPA 440-EVO / SPA 550-EVO

Automatic Selective Soldering System

Automatic Selective Soldering System

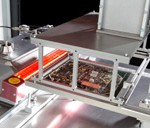

The EBSO SPA 440-EVO / SPA 550-EVO is an automatic selective soldering system with manual loading. Solder bath and solder pump is covered with nitrogen. Designed for automatic soldering of connectors, transformers, coils and other conventional components. Especially for applications which are not suitable for a wave soldering process or to automize hand soldering.

FEATURES

Solder Area 400 x 400 mm (440-EVO) // 510 x 510 mm (550-EVO)

3 axis CNC positioning system with Servo drives

FTP interface to Network

Digital Closed Loop control for N2 flow incl. Standby function to reduce Cost of Ownership

Wave Height control

Autom. Solder wire Feeder and solder level sensor

Flux Tank and flux Level monitoring

Control of all Processparameters

including monitoring functions

including maintenance and error messages

including password protection

Exhaust function monitor

Control lamp freely configurable

Operating state and Maintenance indicator (optional with wireless Network to PC)

Windows CE colour Display

Internal Data management for program storing

Timerfunction

Glashood and Storing compartments

Softwareupdates via USB

ESD-Paint RAL 7035 (light gray) and RAL 7016 (anthracite)

Transport Angle

7° or 0°

Solder Area Options

Standard 400 x 400 // 510 x 510 mm

Solder Pot Features and Options

All Solderpots made of Titanium

Reliability at highest operational availability due to quick release

solder pump

Easy Change Pot system for lead and lead free production

Single solder pot with just 15 kg Solder capacity

Soldering over 2 Solder pots

Dual Solder nozzle for simultaneous soldering

Solder Nozzle Options

Max. clearance at solder side 40 mm

Wetable Nozzles 3 – 12 mm Inner Diameter

Jet Nozzles 5 – 60 mm

Wave Nozzle 300 mm

Special nozzles for Dipping process

Fluxer Options

Max. 4 Fluxers in any combination

Single Spray / Single Microdrop

Dual Spray / Dual Microdrop

Combination of Single or Dual Spray and Microdrop

Adjustable Preheaters

Convection line Preheater

IR Line or Area Preheater

Top Side IR Preheater

Further Options

Fluxer Spray test function

Witness colour Camera including TFT Monitor)

Barcode or DatamatrixCode with BDA (Traceability)

Programming

Offline Editor

including Photo Editing

or Import Functions

EBSO GmbH

Industriestrasse 15 B

D-76767 Hagenbach

Tel: +49 (0) 7273 9358 0

Fax: +49 (0) 7273 9358 28

eMail: info(at)ebso.com

(c) 2013-2015 EBSO GmbH | Alle Rechte vorbehalten. All rights reserved.