E 200

Trimmer / Former

Trimmer / Former

for Taped or Loose Radial Components

| Automatic processing of loosecomponents | Taped components processed with tape feed attachment | |

| An optional vibrating bowi automatically feeds components to the tool. Changeover of tooling is fast and easy with snap-in dies. No screws or tools are required. | Quick tool changeover by rotating the processing head assembly. Attach the tape feeder without any screws or tools. |

| FLEXIBLE RADIAL COMPONENT FORMING SYSTEM |

FEATURES | |

|

||

| The E-200 is rugged and versatile with many standard dies for processing most radial Ieaded components. | ||

| This System makes processing ot taped, loose or tubed radial components easy. The system is suitable tor medium to high volume applications. |

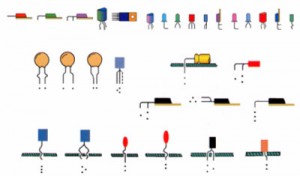

| SAMPLE FORMS: | |

| 1. | Stand-off/snap-in/inline/bolt-circle |

| 2 | Spread or reduce pitch |

| 3. | 90° bend |

| 4. | Outward or inward kinks |

| 5. | Standard TO type forms |

| 6. | Many standard dies |

| 7. | Custom dies and custom applications |

| SPECIFICATIONS: | Bowi Feeder | |||

| Machine | Dimensions |

16“ x 16“ (400 x 400 mm) |

||

| Dimensions |

18“ x 26“ x 13“ |

Weight |

110 lbs. (50 kg) |

|

| Weight |

approx.132 Ibs. (60 kg) |

Capacity |

up to 6,000 uph |

|

| Power |

220 VAC, 50 Hz (11 OVAC, 60 Hz) 200 W |

|

||

| Speed |

variable up to 10,000 cycles/h |

Belt Feeder |

|

|

| Drive |

maintenance free |

Capacity |

up to 10,000 uph |

|

EBSO GmbH

Industriestrasse 15 B

D-76767 Hagenbach

Tel: +49 (0) 7273 9358 0

Fax: +49 (0) 7273 9358 28

eMail: info(at)ebso.com

IMPRESSUM - DATENSCHUTZERKLÄRUNG

(c) 2013-2015 EBSO GmbH | Alle Rechte vorbehalten. All rights reserved.

(c) 2013-2015 EBSO GmbH | Alle Rechte vorbehalten. All rights reserved.